The landfill of Reykjavik, Iceland has implemented for the last decade an active collection of the landfill gas (LG) in order to produce upgraded biomethane used as transportation fuel in the capital area. In 2016, 1.900.000 Nm3 of upgraded biomethane was produced and sold in fuel stations in the capital area. In order to fulfil the increasing demand in biomethane, it is necessary to collect more LG while keeping the methane content in the upgraded gas as high as possible (≈95% CH4). Increasing LG recovery while keeping biofuel grade can be achieved by combining the extension of the gas collection area and use methods to increase the efficiency of the existing system.

Production of methane biofuel requires a high composition of biomethane (>95%). In order to reach such composition and based on a water scrubbing technology for upgrading, it is necessary to limit Nitrogen and Oxygen content within the landfill gas. In addition, to avoid landfill gas emission and to answer the market demand, it.

Reykjavik landfill can be seen as a series of bioreactor systems. Each of the cells is closed with a soil cover and waste composition and age is known. The gas collection system is installed usually in a period of 0,5-2 years after the closure of the cell. In addition, the older part of the landfill equipped with a gas collection system is used as a test area for leachate recirculation.

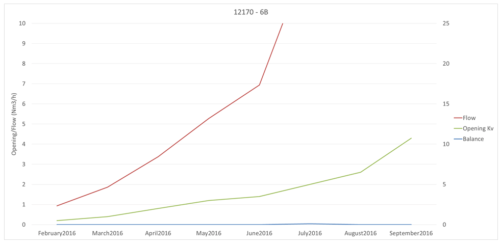

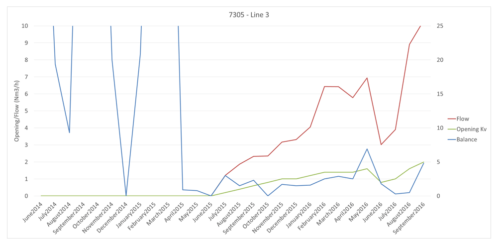

The extension of the area where LG is collected is limited by the filling rate of the landfill on one side and by ageing cells where gas production is almost nonexistent on the other side. Therefore, the best room for improvement in quantity and quality relies on the optimization of the operating system. To achieve quality and quantity goals, an advanced monitoring plan of the landfill was implemented since the year 2014 with the collaboration of the Environmental Engineering company ReSource International (RSI) ehf. and the landfill operator SORPA bs. The monitoring plan is implemented as a multi-layer strategy including spatial and temporal considerations.

Reykjavik landfill can be seen as a series of bioreactor systems. Each of the cells is closed with a soil cover and waste composition and age is known. The gas collection system is installed usually in a period of 0,5-2 years after the closure of the cell. In addition, the older part of the landfill equipped with a gas collection system is used as a test area for leachate recirculation.

The extension of the area where LG is collected is limited by the filling rate of the landfill on one side and by ageing cells where gas production is almost nonexistent on the other side. Therefore, the best room for improvement in quantity and quality relies on the optimization of the operating system. To achieve quality and quantity goals, an advanced monitoring plan of the landfill was implemented since the year 2014 with the collaboration of the Environmental Engineering company ReSource International (RSI) ehf. and the landfill operator SORPA bs. The monitoring plan is implemented as a multi-layer strategy including spatial and temporal considerations.

Landfill gas is collected from closed landfill cells using a network of gas wells. Once collected, the gas undergoes an upgrading process, often through water scrubbing, to separate methane from other components like nitrogen and oxygen. The result is high-purity biomethane (>95% CH₄), suitable for use as a renewable transportation fuel.

Reykjavík’s system is notable for combining advanced environmental monitoring, drone-assisted surveying, and data-driven optimization. By treating landfill cells as bioreactors and continuously adjusting gas well operations, the site maximizes both the quantity and quality of gas recovered.

High levels of oxygen and nitrogen dilute the methane content, reducing the energy efficiency of the biomethane. These gases also interfere with the upgrading process and may pose safety risks. Controlling their levels is critical to producing fuel-grade biomethane.

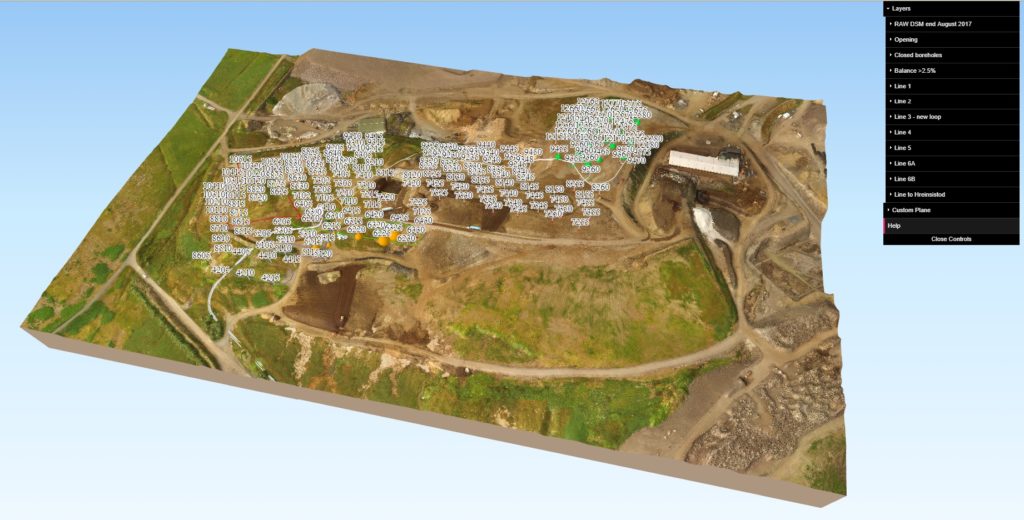

Drones provide high-resolution photogrammetry, 3D modeling, and vegetation analysis, offering precise data on site changes. They allow landfill operators to detect methane leaks, monitor surface conditions, and plan cell operations more effectively, all while reducing manual fieldwork.

Data from sensors, weather patterns, and gas composition are used to fine-tune gas well operations. Over time, this allows the identification of performance trends, system inefficiencies, and environmental correlations, leading to smarter maintenance and system design.

Yes. The strategies developed in Reykjavík are scalable and adaptable. With proper baseline studies and system design, other landfills can replicate this model using monitoring tools, data platforms, and customized gas collection strategies.

Efficient gas recovery reduces greenhouse gas emissions, improves air quality, and decreases reliance on fossil fuels by providing a renewable energy source. It also reduces odor and improves site safety by minimizing uncontrolled gas emissions.

Monitoring occurs on both manual and automated schedules. Parameters include gas composition, atmospheric pressure, leachate levels, soil moisture, and weather data. Drones are also used for spatial mapping and vegetation analysis.

The focus is on continuous improvement through better system design, predictive maintenance, and expansion of monitoring capabilities. Future plans include integrating wireless sensors and developing web-based tools for broader application.

ReSource International (RSI) ehf. is an environmental engineering company that co-led the development and implementation of the monitoring and optimization system in collaboration with SORPA. They specialize in data-driven environmental solutions for energy and waste sectors.

Alessandro Sarno runs ReSource Sverige AB as CEO and Co-founder. The company provides environmental monitoring solutions and consultancy within energy and waste management sectors. With a background from Lund University, he spearheads the application of innovative technologies like digital data platforms and drone-based methane monitoring. His versatile approach and commitment to transparency drive the company's expansion of data-driven environmental services across Sweden and Europe.